Our Company’s product range embraces a wide range of machines and equipment for the manufacture of electric cable and steel wire rope. In addition to high-speed tubular stranding machines, cage-type stranding machines and central stranders, also included are drum twisters for the cable industry.

In German, drum twisters are referred to as universal stranding machines and this is a much better descrption of the applicational role for these machines – all purpose machines which can be used universally. Drum twisters are usually to be found wherever cable is produced

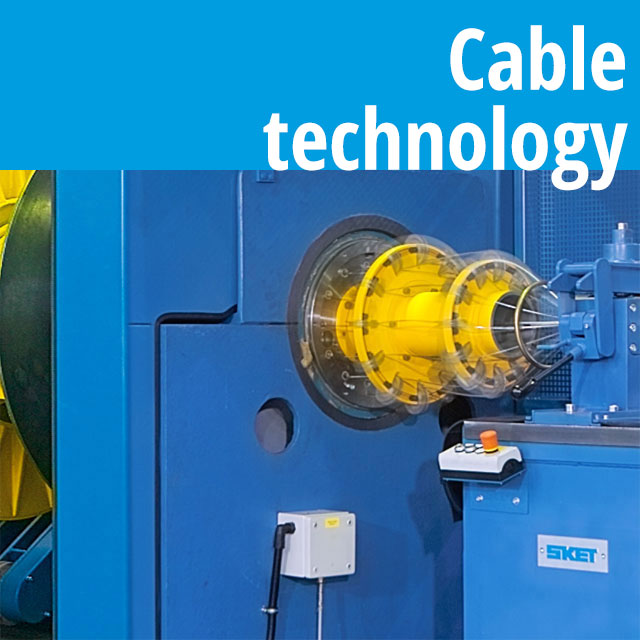

AT SKET we have been manufacturing and supplying drum twisters – a relatively recent machine addition – for over fifty years. The machines are tailor made to the product specific requirements of the user and right from the planning stage what is important to the customer is taken fully into account and appropriate solutions are proposed. As with other systems, this machine system too follows the trend towards the development of ever bigger diameters and cable lengths. Pay-off and take-up bobbin diameters today are typically in the range 1000 to 5000 mm. The throughput weights can be more than 50 tonnes. In this way the movement in the cable industry towards ever longer production lengths is taken fully into account and the suitability of the drum twister for the manufacture of offshore energy cables is ensured.

Today SKET drum twisters are in use in many cable works worldwide where they demonstrate their efficirncy and their reliability on a daily basis. What can be better proof of this than the placement of a repeat order by one of our North American customers for the supply of a drum twister towards the end of this year!