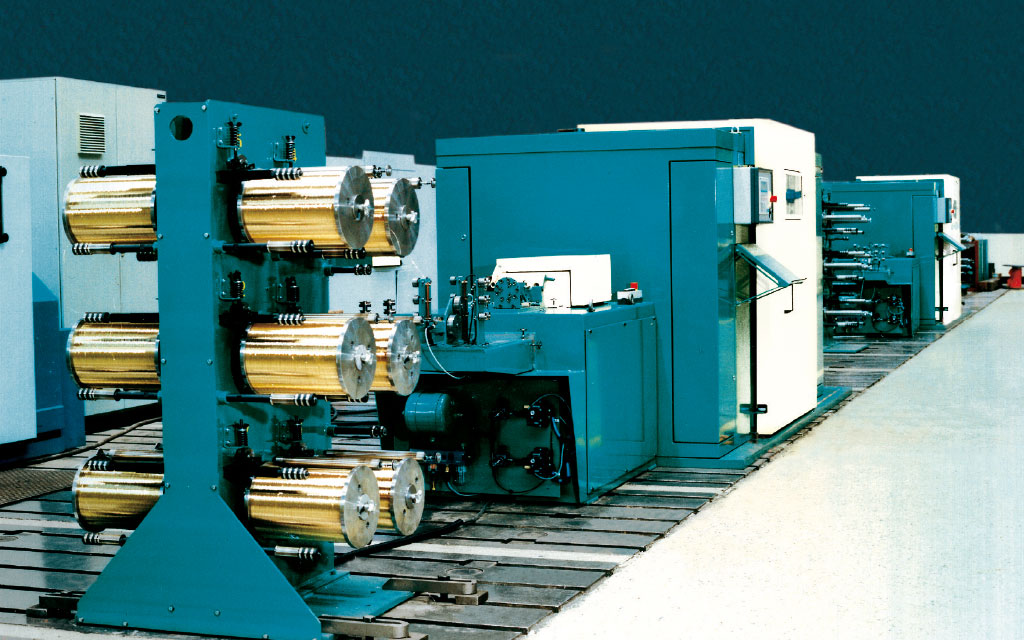

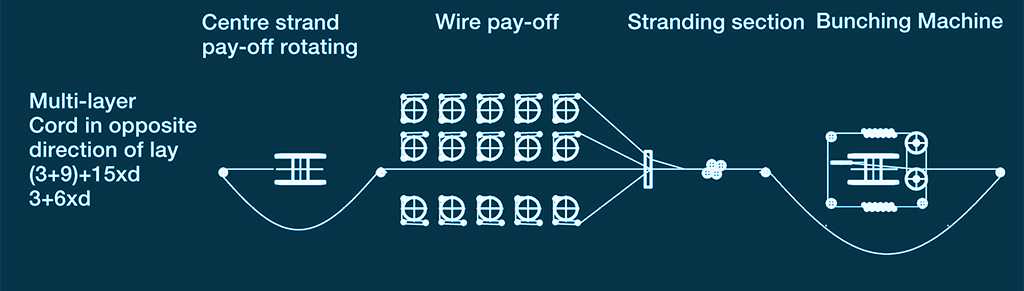

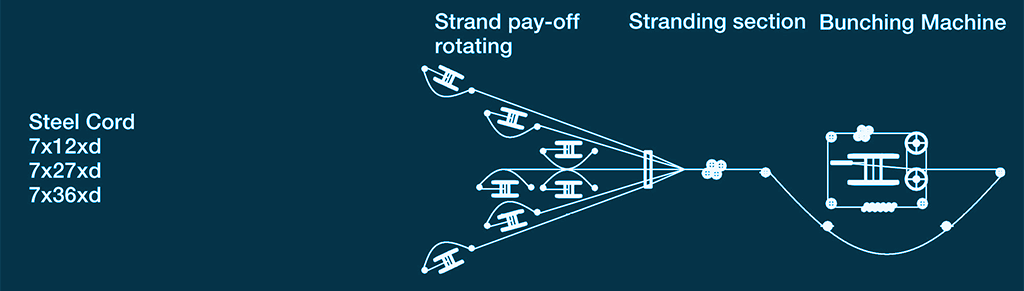

For the manufacture of steel cord wire strand, SKET Verseilmaschinenbau GmbH offers the MSDN double-twist bunching machine range which operates on the OUT – IN stranding principle.With this principle the wire supply bobbins are arranged outside the machine and the stranded product – the steel cord strand – is produced and taken-up inside the rotor section. The size of the machine is thus determined by the size of the take-up bobbin. This type of machine is used mainly for the production of

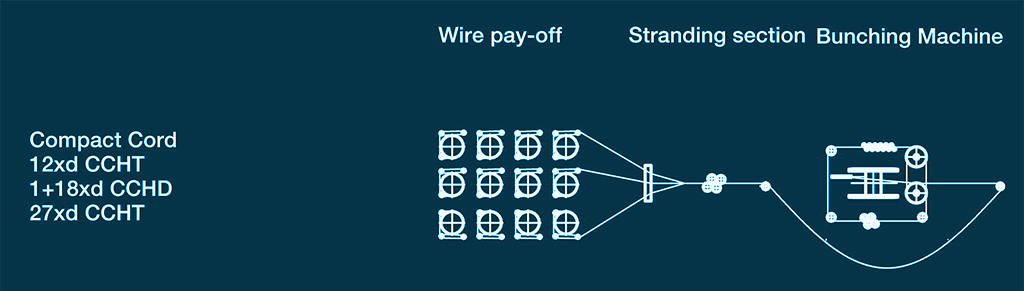

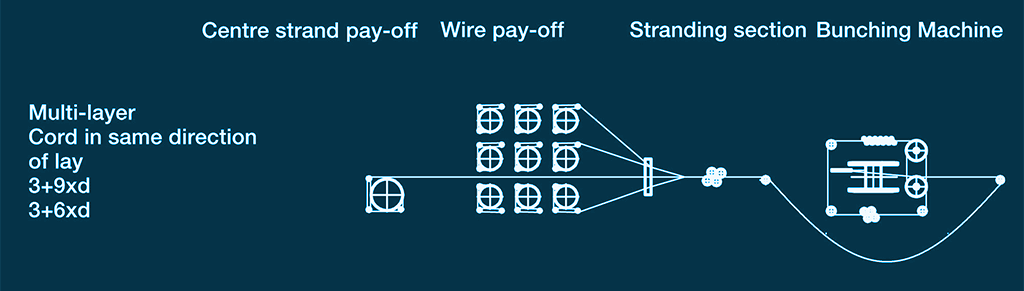

- multi-layer steel cord strand

- compact cord constructions and

- steel cords.

The main advantage offered by the MSDN range is its flexibility in terms of the number and size of its wire supply bobbins, as a result of which long machine running times are possible. The basic construction of the machines is the same for all sizes and it is then tailored to the particular technological requirement.

- centre strand pay-off rotating or stationary

- wire pay-off tangential or via a flyer

- a stranding section comprising torsion limiters, a lay-plate, a stranding die and a pre-twister

- a rotor section housing the rotor, the haul-off, a straightener, an overtwister and a take-up.

By using standard machine assemblies in a variety of different machine configurations, maintenance is simplified and the need for spare parts is kept to a minimum.To meet the varying requirements of our customers, SKET offers the MSDN machine system to accommodate take-up bobbins having a flange diameter of 250 mm, 315 mm, 420 mm or 560 mm. Standard trade norm fi nished product take-up bobbins including B40, B60 and B80 (excluding the MSDN 250) can be accommodated in all machine sizes. Other specials on request.

With the MSDN machine range, SKET has developed a highly flexible machine system which can be easily adapted to the particular requirements of the customer.

The Technical Characteristics of the MSDN Range

Double-twist bunching machines of the MSDN range for the manufacture of steel cord are characterised by the following technical features:

- compact, space saving assembly construction

- no requirement for a special machine foundation and vibration dampened rotor arrangement

- long machine running times due to the use of large pay-off bobbins

- easy setting of the wire or strand tension via spring adjustment of the bobbin brakes

- constant tension maintained in each wire via an “active” dancer controlled bobbin brake

- flexible speed selection for the pre-twister and core back-twist units through the use of a separate A.C. drive

- use of a special pre-former instead of rotating pay-offs for the manufacture of compact and multi-layer cords

- integral loading unit for the loading and unloading of the take-up bobbin

- wire break monitors for each individual wire/strand at the forming point, in the rotor section and on the cradles (data transfer without slip-rings)

- noise insulated safety guards