Solid stranding machines are characterized by a very long service life despite permanent and rough use in the steel rope and cable industry. Still today there are 40-50 year old machines in ropes and cable factories around the world that reliably manufacture ropes and cables in compliance with quality parameters. Fully customized overhauling of lines is one possibility to secure values, nowadays.

In general, it can be stated that a revision and/or an upgrade often only costs a fraction of a new machine and greatly reduces the efforts in the subsequent maintenance cycles.

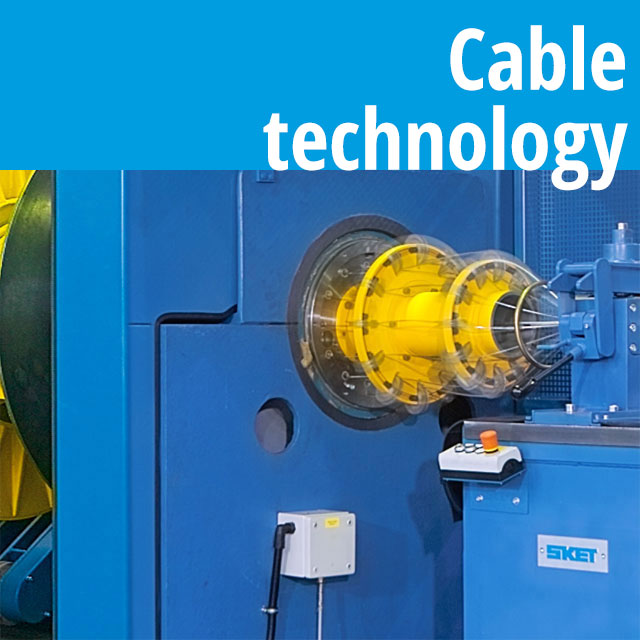

SKET is a partner when it comes to complex machine overhauling. Not only the engineering, but also manufacturing, assembly and risk assessment is part of our scope. SKET Verseilmaschinenbau GmbH as a traditional and experienced stranding machine manufacturer would like to show possibilities and document them in 2 recently received orders.

Recently SKET overhauled a complete planetary cage for armoring purposes. The old drawings were reengineered to modern manufacturing drawings. This included also improvements coming from suggestions by our customer. We did also 3D modelling for essential parts to have a bases for a FEM-analysis. In this way, weak points in the design could be identified and components were optimized.

After confirmation of all needed documents all parts were manufactured respectively purchased and assembled inside our workshop. In addition the cage was completely fitted with new electrical components including a modern slipring unit.

Finally, the documentation including risk assessment has been made to have the machine ready for a second lifecycle.

Furthermore, SKET has overhauled a 40 year old support roller tubular stranding machine for a customer in Lithuania. The machine is one of the most important machines for him and produces combined ropes consisting of fibers / yarns and steel wire strands. SKET revised the running surfaces of the 5 tubes, made new cutting of the retainer for the brake discs and manufactured new brake discs. Finally, all of the support rollers were renewed and finally turned at SKET.

The customer is now in a position to use the machine in rope production for years to come. The total cost of the overhaul was around 10% compared to a new machine of the same size. After the machine was successfully restarted in his company, we were pleased about the positive feedback from our customer: “Machine is running very well – compare as it was before is like “ day and night “ So I would like to say many thanks for you and SKET team made well job. In soon future we are planning to do the same with another Closer SV 6+1/80 and I hope that SKET will agree to help us again.”

If you are interested in a revision or an upgrade, please do not hesitate to contact us directly.